User’s Manual

The RSM circulates and controls warm water for radiant heating. It would typically be used to heat a concrete slab via embedded pipes, but can feed pipes in a poured wall, attached to a wood floor, or in a greenhouse plant bed as well. The module provides precise radiant loop temperature control (±1°F) by constantly monitoring return water temperature and, upon demand, injecting heated water from any of a variety of sources: water heater, boiler, or solar storage tank.

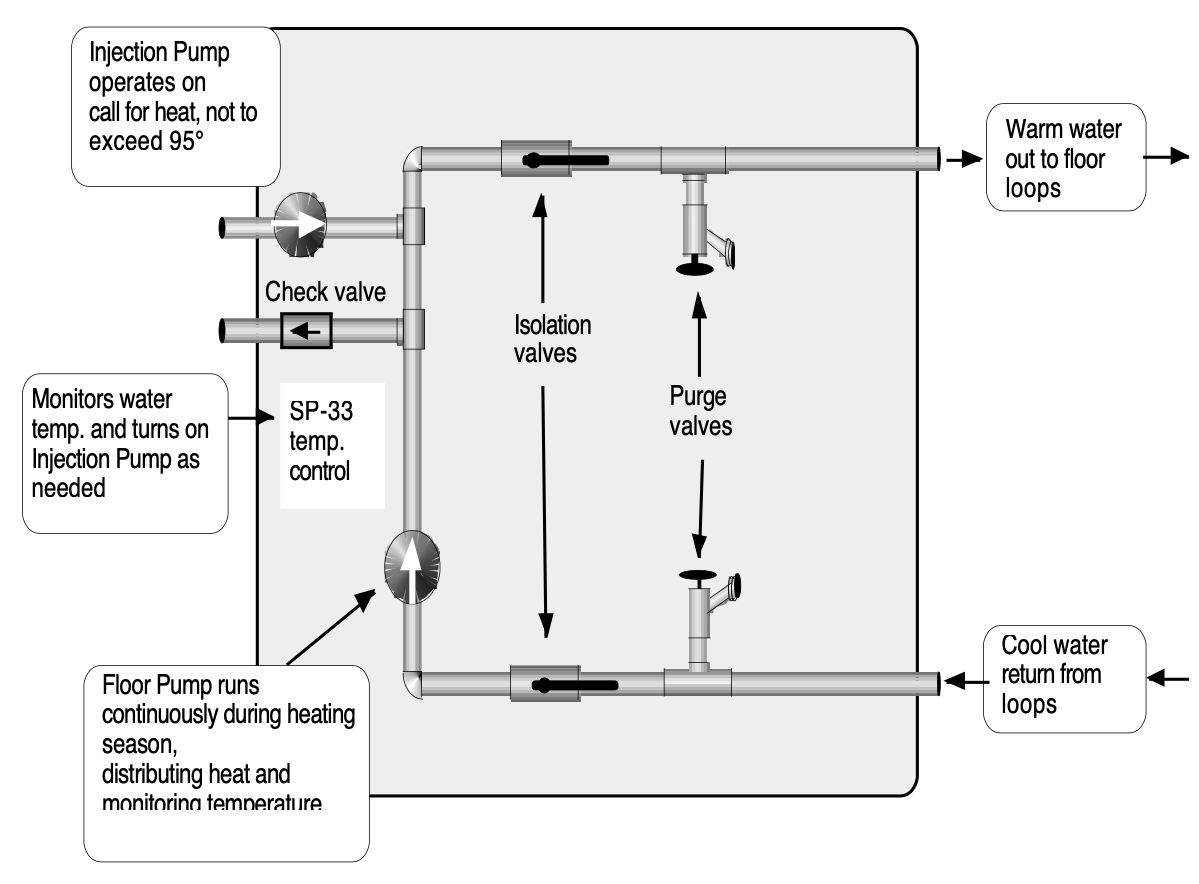

The module includes a continuous circulation pump (typically a Taco brand 008B or 009B), an injection pump (Taco 006B), maintenance valves, and a temperature control. The RSM-1B is mechanically the same as the RSM-1. The difference is that it uses one SP-33 for both desired temperature and high-limit control.

Quick Information List (the essentials)

- How do I adjust the temperature? The radiant loop temperature is set by the dial inside the control box labeled “SP-33”. This is under the pop-off portion of the cover; you do not need to unscrew the whole cover. [You may have the option of a remote dial (“RSP-33”) to perform this function mounted on a wall in a convenient location.] Most people find one setting works for the entire heating season. Since radiant heat is a gentle process, if you change the temperature setting allow several hours to feel the difference.

The temperature of the hot water (both for domestic use and to supply the RSM) is set by the thermostat on your water heater, not the SP-33.

- When should I turn the heating system on and off? The system should remain on during the heating season. If the building is to be unoccupied you may wish to turn the system off if there is no danger of freezing, or you can just turn the SP-33 thermostat down to maintain a safe temperature for house plants and/or plumbing pipes.

Outside the heating season we recommend the system be turned on for fifteen minutes at least once per week. A timer can be installed to do this automatically.

- How do I tell if the RSM is working? When the power is on the “power” or “on” LED on the SP-33 should glow and the circulation pump should be running. The pump makes a slight hum and, after running a few minutes, will be warm to the touch. As more heat is needed the SP-33 will click its relay (“1” LED will light) and turn on the injection pump. You can cause this to go on and off by adjusting the SP-33 dial.

Description of Operation

When the RSM is turned on the circulation pump and SP-33 control are energized. In a typical home installation the unit would remain on throughout the heating season. While the main function of the RSM is to add heat to the slab, this continual circulation helps distribute heat gained through passive means — making the whole slab part of the passive solar mass — and allows continuous slab temperature monitoring.

The RSM-1 uses an Independent Energy set point control (thermostat), SP-

33. One of its LEDs indicates power to the unit and another (marked “1”) indicates the internal relay is activated (output power to the injection pump is on). The SP-33 is set by the user between 70 and 85°F dependent on comfort requirements in the dwelling. Since this is slab temperature and not air temperature, the setting usually does not need to be changed once a comfort level is determined. The SP-33 compares a temperature sensor located on the radiant loop water pipe with the dial setting. If the slab water is cooler than the set point, heat input is called for by passing 110vAC to the injection pump, which begins mixing hot water in with the cooler water circulating through the floor loops. Since normally the hot input water would be above the high limit set internally by the SP-33, the addition of this heat will soon bring the temperature up and the injector pump will shut off.

During this period the heat is circulated through the slab. In a few seconds SP-33’s sensor will cool down and the injector pump will again be turned on. This cycling of the injector pump will continue until the whole radiant area (slab, wooden floor, or walls) has reached the temperature set on SP-33. The period of this cycle will depend on several factors, the main ones being temperature of the inlet water and circulation flow rate.

Hydronic Radiant Heating Module

Maintenance

Since the pumps are lubricated by the water they pump they require no maintenance, but if they sit too long without running the water can leave deposits that will prevent the pump from being able to start on its own. It will then have to be taken apart and freed up. To prevent this, we advise you to run the RSM for five minutes at least once each week during the non-heating season. An electronic timer can be installed to do this automatically.

The shutoff and purge valves are used for maintenance only and do not need to be changed in normal operation. In the event of a leak in the floor loop pipes unplug the RSM and shut both isolation valves.

If feed water pressure is lost turn off the RSM immediately to prevent damage to the pumps. Warranty is void if the module is ever operated dry.

Should maintenance be required for the hot water tank or hot water pipes, before draining the water heater switch off the RSM and close the ball valve that supplies hot water to the RSM. Only after water pressure is restored, the tank is full, and air has been purged from the potable lines is it safe to open the RSM feed valve and turn the unit back on.

The whole radiant floor piping system should be flushed at least once per year or after any introduction of air into the hot water lines. This is accomplished by attaching hoses to the purge valves and using them and the isolation valves to force water through each loop one at a time.

Troubleshooting

|

Symptom: |

Likely Causes: |

|

1) Pumps never run. |

1a) If SP-33 Power LED is not lit check AC power at outlet. |

|

1b) If above is lit but circulation pump is not running then the pump or its wiring are bad. |

|

|

1c) Open pop-off cover of SP-33 and move switch to ON. This should force the output on (“1” LED and injection pump will probably come on.) Note which of these things happens and call Solar Consultants. Return the switch to AUTO and replace cover. DO NOT allow the injector pump to continue to run hot water into the loops more than five minutes. |

|

|

2) Circulation pump is running but no heat is being supplied to the house. |

2a) If the injection pump is running, feel the pipe from the water heater to that pump (NOT the pump itself) and see if it is warm. If it is not warm, then your water heating is faulty or a valve has been closed, not allowing the injection pump to circulate hot water into or cold water out of the loops. |

|

2b) If the injection pump is not running, perform the test in 1c), above. If the injection pump starts up you should be able to feel the pipe from the water heater getting warm, and then the pipe feeding the radiant loops get warm. If all this performs as it should the problem is most likely in the SP-33 or its temperature sensor. DO NOT allow the injector pump to continue to run hot water into the loops more than five minutes. |

|

|

3) Noises |

The pumps are lubricated by the water they pump. The noise should be a steady hum. Pinging or a soft “popcorn popping” indicates air in the lines; this is not a dire emergency but can reduce circulation and should be dealt with by purging before… Screeching indicates bearings shot; turn off the RSM-1 immediately. |

Specifications

Circulating pump flow (GpM): > 1 Electrical requirements (Watts @ 115vAC) typical: 100 maximum: 220 Size: h 24″ w 24″ (Allow area at each end for pipe connections.)

Options:

-

- Compact model requires only 20″x20″ surface.

- Remote “desired temperature” dial for SP-33 thermostat — can be installed anywhere in the house.

- Remote digital “current temperature” and “desired temperature” readout.

- Direct Current models available.

Design changes and part substitutions may be incorporated in custom or future systems.

Warranty

Parts and workmanship are warranted by Solar Consultants for one year from the installation date. Individual parts, especially tanks, pumps, and controls, are covered by additional manufacturers’ warranties. After the first year, replacement of manufacturer warranted parts may incur a labor charge.

Independent Energy Goldline solar controls carry a ten year warranty. Replacement the first two years is at no charge; two to five years at twenty-five percent of list price; five to ten years at fifty percent of list. Taco pumps have a one year replacement/repair warranty for the electrical portion and three years for the cartridge, which contains all the moving parts.

Glossary

Ball Valve an in-line valve that controls fluid flow. They are preferable to other types in that they do not restrict flow when open and never need a washer or seal replacement.

Check Valve an in-line valve that allows fluid to pass in only one direction.

Circulation Pump the larger of the two pumps in an RSM-1, it continually moves water through the floor loops. It stays on throughout the heating season.

Diverter Valve or Bypass, a T ball valve situated to direct the solar heated water into either the cold inlet of the backup water heater (“preheat”, or winter operation) or directly feed the domestic hot water line (“solar only”, or summer operation).

Expansion Tank a small tank containing an air-filled bladder surrounded by fluid. As the fluid expands it compresses the air. This evens out pressure fluctuations that would be caused by temperature change.

Injection Pump the smaller pump on an RSM-1, it is turned on by the controls as needed to add hot water to that circulating through the floor.

Key Vent a bleed valve used to purge air from a pipe. It is opened with a screwdriver or square key similar to a skate key.

LED, Light-Emitting Diode an efficient and long-lasting semiconductor used as an indicator on many controls.

Pressure Relief Valve a safety valve which opens to dump fluid or water if the pressure goes beyond its set point. Sometimes the set point is adjustable; on solar loops it may be set from 30 to 125 p.s.i. On a standard water heater the PRV is combined with a temperature probe so that it can open if either pressure or temperature exceed safe limits. The outlet of the valve is sometimes piped to the drain pan, the crawl space, or outdoors.

Radiant Loop Low-temperature hydronic heating uses large areas as the heat- bearing and distribution surface, as distinct from high-temperature radiators.

Pipe laid for radiant heating, therefore, is set out in long runs that loop in a serpentine pattern through the mass. A small floor may have only one loop, but often a house will have several loops in zones. These may have valves so that they can be regulated individually, but often these are not needed.

RSM-1, RSM-1B Radiant Slab Module: the circulation pump, injection pump, control boxes, wiring, piping, and valves manufactured by Solar Consultants for hydronic heating. The original model used separate SP-33 and -34 controls; the B model uses only an SP-33.

Solar fluid The fluid consists mostly of water, mixed with an anti-corrosive buffer, propylene glycol, or ethylene glycol.

Solar loop the portion of the system that carries the fluid that passes through the collectors to be heated by the sun. This fluid is (in our systems) kept completely separate from the domestic water. Heat passes from the solar fluid to the domestic water in the heat exchanger.

SP-33 or -34, Set Point Control, or thermostat. This white box compares a dial setting with a thermistor temperature sensor to switch a relay which can turn a pump or other load on or off.

Tempering Valve an automatic thermostat mounted at the hot water outlet of a water heater. If the outgoing water is above its set temperature, the valve allows cold water to mix in.

Send Us a Message

Contact Info

Fred Stewart

Licensed plumber and solar thermal system designer

Tom Willis

Licensed plumber and NABCEP-certified system designer

Richard Copsey

Installer/technician