Pressurized Solar Water Heater featuring Rheem Solaraide integral heat exchanger tank

View PDFContact UsUser’s Manual

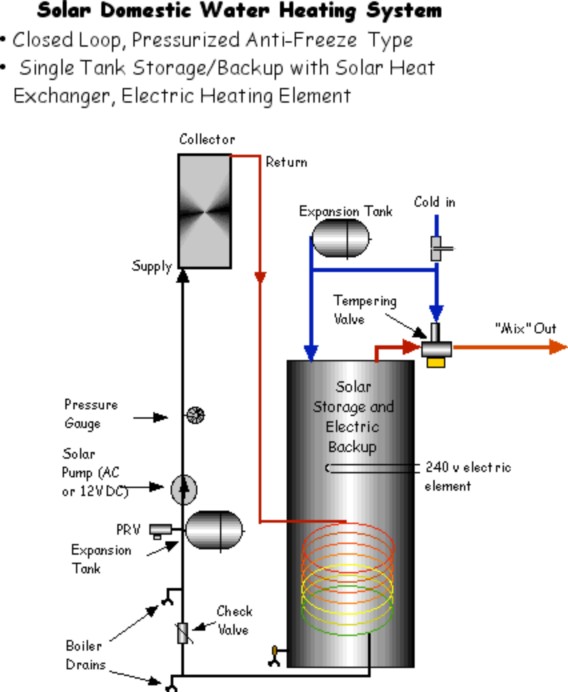

The pressurized solar water heater has the following characteristics:

- Sealed solar fluid loop containing a solution of propylene glycol antifreeze and water.

- Heat exchanger is wrapped around the tank, so only one pump is needed.

- Uses industry-standard Armstrong/Wilo or Taco circulator (pump). Other brands can be substituted for replacement without system redesign.

Components

The solar storage and backup water heating are accommodated in one tank — the Rheem Solaraide HE. (This Rheem-manufactured water heater is also sold under the Richmond and Eagle Solar brands and yours may have any one of those labels, but it is referred to in this manual as a Rheem.) The unit comes with an electric element to provide backup heating to the upper portion. [This element may be replaced by an external gas-fired heater, or a separate water heater may provide the backup in some installations.]

The solar loop of the system consists of a two drain/fill valves with a check valve between them, pressure gauge, pressure relief valve, expansion tank, cast iron circulator to move the fluid through the collectors, and the Rheem water heater’s heat exchanger. The solar fluid is water and propylene glycol. [It would be safe to use ethylene glycol in the system instead if desired.]

The pump is controlled by a differential temperature control, typically an Independent Energy GL-30, mounted on the side of a tank or wall near the solar pump. This uses 10kΩ sensors at the top of the collector array and at the bottom of the potable water storage tank to monitor temperatures.

Pump

- Taco 007ci

- Taco 008ci

- Astro 30/Wilo 16 ci

Collector(s)

- SolarHot Silver

- SolarHot Platinum

- SolarGenix Winston

Description of Operation

When sunlight hits the collectors and their temperature rises to fifteen degrees higher than that of the coolest potable water at the bottom of the storage tank, the differential temperature control switches on 120VAC power to the pump. The solar fluid circulates through the collectors and the heat exchanger, thereby warming the water in the tank.

Pumping continues until the collectors and the stored water come within four degrees of each other, then the pump turns off. On a day with intense mottling of clouds and sun it is possible for the pump to stop and start several times. This happens

especially when the storage water has already been heated to near collector temperatures.

The control includes an adjustable high temperature limit. When the lower storage tank temperature reaches the limit — usually set inside the control at 130 to 160°

— the control shuts off the pumps even if the collectors are still hot. This would typically occur near the end of a sunny day when little domestic hot water had been used.

If the storage tank has reached an excessively high temperature the control may turn on the pump even after the sun is down in an attempt to shed excess heat. This mode is activated by an optional external snap-disc thermostat.

At times when solar heating has not brought the top of the tank to full temperature, the backup heating thermostat will turn on the electric element or gas burner. This thermostat is behind the access panel on the water heater and is independent of the solar control.

Installation

This section is intended to inform the system owner of some of the considerations and logic that went into the installation of solar equipment. It may be helpful if a re-roofing, renovation, or other change demands part of the system be moved. This is not intended as a complete training course in installing the equipment from scratch.

Collectors and Pipes

Your collectors may have been mounted using any of several methods, depending on whether the feet are attached directly to the collector frames or a separate aluminum frame was fabricated to hold the collectors, they are parallel with the roof surface or held up with legs, etc. In all cases each foot has a stainless steel lag bolt that penetrates the roof into solid wood (except for standing seam roofs, where a clamp may be used to avoid penetration), and each penetration is sealed. The ideal mount faces the collector array South at approximately a 45° angle from horizontal, although the performance will not suffer greatly if they do not face due south or attain a 45° angle.

If the collectors must be moved for roof repairs consult a solar installation professional beforehand to ensure the system is shut down and drained properly and the collectors are handled properly.

Maintenance

The propylene glycol antifreeze mixture in the solar fluid should be tested or flushed and recharged every five years.

Your water heater includes an anode rod that protects it from corrosion from the potable water. It also should be checked at least every five years. If the electric element is wired up, turn off the electric element’s 240V (double) circuit breaker or pull the disconnect before draining any water or unscrewing the anode. To check the rod, turn off the cold water inlet and drain off the hot water pressure down to the level of the top of the tank, then unscrew the sacrificial anode rod — it is the large hex-head in the top of the storage tank (water heater) — and pull it up to examine the rod. If it is deeply pitted or more than six inches of core wire is exposed at either end of the rod, replace it. After the anode is back in place and the cold-water valve is back on, open several hot water taps long enough to blow air out of the tank and lines before restoring electric power to the element.

Since the pump is lubricated by the fluid it pumps, it requires no maintenance, but if it ever sits a month or so without running the fluid can leave deposits that will prevent the pump from being able to start without being taken apart and freed up.

If the system must be left not operating for more than a few days, see :Shut Down”, below.

Outdoor pipe cladding, insulation, and caulk should be checked annually. Insulation can be damaged by animals, branches, and ultraviolet rays. In all new installations, we protect the insulation and sensor wire with aluminum cladding. As long as that is in place no maintenance is expected.

If the insulation is not protected by a jacket, it should be repainted with an exterior glossy paint. All joints in insulation should be sealed. Pay special attention to where insulation meets the collector or roof flashing. Also check the wire any place it is exposed. The wire should be protected from sunlight. Especially vulnerable if exposed are the two connections to the temperature sensor, located at the exit (“return”) pipe at the top of the collectors. Seal the crimp terminals or wire nut connectors with silicone sealant to keep water out. Water will corrode the connections and cause control problems

Indoor pipe insulation, where exposed, should be checked every few years.

Patch any areas where shrinkage or damage has caused gaps to form, using insulation rated for high temperatures (rubber foam, isocyanurate foam, or fiberglass; not plastic foam.)

Animals – cats in particular – are attracted to the warmth of the system. The top of a tank makes a great place to sleep. But they also practice scratching on the insulation, and fur is not the best coat for the control and pump. You may have to wrap screen wire around the area to keep them from getting at it. Most solar heating systems use propylene glycol antifreeze, which is not harmful to drink — at least when it is new. But if your system contains ethylene glycol antifreeze instead of propylene, no pets should be allowed access to the pump area, in case of a release or leak of fluid.

Shut-Down

If you plan to be away from home or for some other reason no hot water will be used for days at a time, leave the power to the solar control ON. You may, however, want to turn off the power to the backup heating element and close the whole house water supply valve, or at least the hot water shut off. If no hot water is being used it is possible for the solar loop to overheat. For safety the system includes two pressure relief valves, which open if pressure builds too high from overheating.

The one on the top of the water heater can discharge a good deal of water, while the one on the solar loop can discharge a small amount of antifreeze into the drain pan. There are several ways to avoid this inconvenience:

- Arrange for someone to use hot water while you are away.

- Open the control cover and move the slide switch from “Auto” to “On”. This will turn the pump on so at night it can cool the glycol. Be sure to switch it back to “Auto” when you return.

- Secure a tarp or cover over the faces of some of the collectors (at least half).

- Covering the collectors completely is the best way to avoid overheating the fluid during a power outage.

If the solar control has to be left turned off during the day – unless it is extremely overcast – and the collectors cannot be covered, the antifreeze mixture should be drained into a clean bucket and at least one of the boiler drains left open to relieve any pressure. A typical system will hold about four or five gallons. Unplug the solar control to make sure the pump will not turn on until the system is recharged with glycol.

Consult a solar professional to have the antifreeze tested and the system recharged. You do not need to drain the water storage, just the glycol.

Should maintenance be required for the hot water tank or hot water pipes, turn off the water heater’s double (240V) circuit breaker before draining any water. This is to protect the backup electric element from damage. After water pressure is restored and the tank is full, purge air from the hot and cold lines before restoring electricity to the heating element. Electricity to the solar pump control should be left on even if the water tank is drained, so long as the solar fluid lines are not disturbed. This allows the system to relieve some of its heat to the tank, even though it is empty.

If for any reason the solar loop is taken out of service, i.e., the pump will not be running or the pipes will be cut for renovations, the glycol should be drained into a clean bucket and the collectors flushed thoroughly with water.

Troubleshooting

If you are ever uncertain of whether the sun is heating your water or not, try turning off the backup by switching off the water heater element 240V breaker or power or gas valve of the gas backup. Be sure that power is still on to the solar control. Leave it this way for at least a day. You should continue to have hot water as long as there is a reasonable amount of sunshine and you are not using more hot water than the system was designed to supply.

The best preparation for ensuring your system works well is for you to become familiar with the sounds the system makes in normal operation. Usually this is limited to a steady, barely audible hum of the pump and a slight fluid motion in the pipes

By feeling the pipes on a sunny midday you should be able to tell a difference in the temperature of the fluid going up to the collectors and that returning. The return fluid should be warmer, although the temperature difference may be slight. And at the end of a sunny day when you have not been using a lot of water, the tank should be warm all the way to the bottom. But be mindful as you make these tests: any of these pipes can be scalding hot!

Another troubleshooting tool is the pressure gauge. Most systems will run with as little as five pounds of fluid pressure, but were probably charged with fifteen to thirty when installed. There may be a mark on the gauge or a note written on the tank showing the original pressure. If the pressure has fallen it may be due to a pressure blow off from overheating, a dripping drain/fill valve, a punctured expansion tank, or a leak at some other fitting or in the collectors. If the pressure is low when cold but high when hot it indicates air in the lines or a faulty expansion tank. (See next paragraph.) If the gauge is near the pump you may be able to see a slight change in pressure (4-8 psi) as you switch the pump off and on. This is a good indication that the solar pump is circulating fluid.

Pressurized systems are normally very quiet; the pump hums softly, the fluid runs smoothly. A gurgling sound from the pipes or a “popcorn popping” sound from the pump indicates air in the lines. Large gushes of air should be corrected immediately, as oxygen, antifreeze, and heat combine to form corrosive organic acids that can corrode your collectors.

The temperature sensors are thermistors with a negative coefficient of resistance to temperature, so a low resistance is analogous to a high temperature. The voltage to the sensors is low, so it is perfectly safe to work with them with the differential temperature control power on. A quick way to test the basic function of the control: if it is powered and switched to “Automatic” mode and the pump is not running you can short the collector sensor leads (imitating a hot collector) to make it turn on; if it was

pumping already, leave the collector leads alone and short the storage leads (imitating hot storage) to see it turn off.

The pump body normally runs hot to the touch. It should never become so hot as to discolor or blister the paint, however. If the system does not seem to be circulating heat down from the collectors (that is, pipes are not warm, tank does not get warm near the bottom) and the 007 or 008 pump is hot (and possibly humming) and especially if it fails the pressure change test mentioned above, then the pump is not circulating fluid. Unplug the control and call a solar repairman. You may need to drain off some solar fluid or cover the collectors to prevent overheating until the pump is repaired.

The solar heating system is functionally independent of the backup water heating or space heating systems.

Notes Regarding Parts

- collector(s) typically SolarHot Gold, Platinum, Alternate Energy Technologies AE-32, Chromagen, or Solargenix Energy Winston Series.

- water heater: Richmond 80E or Rheem 81V80HE (Rheem Manufacturing, P.O.Box 244020, Montgomery, AL 36124)

- solar fluid pump: Astro 30 or Wilo 16 cast iron, (Armstrong Pumps, Inc., 93 East Ave, North Tonawanda, NY 14120); or Taco 007 or 008 cast iron, flange fitting, (Taco, Inc., 1160 Cranston St., Cranston, RI 02920)

- differential temperature control: Goldline GL-30 (Independent Energy Inc., East Greenwich, RI)

- All other parts are standard items obtainable from local plumbing supplier. If you are replacing the expansion tank make certain the new one is rated for fluid temperatures >180°F.

Specifications

Electrical requirements (Watts @ 120vAC) typical: 40 maximum: 100

Options:

- Thermostatic mixing valve (tempering valve) for water heater outlet.

- Dial thermometers to indicate fluid temperatures.

- Remote temperature readout. Can be installed up to fifty feet away.

- Direct current models available.

Design changes and part substitutions may be incorporated in custom or future systems.

Warranty

Parts and workmanship for a complete system installed and maintained by Solar Consultants are warranted by Solar Consultants for one year from the installation date. Individual parts, especially tanks, pumps, collectors, and controls, may be covered by additional manufacturers’ warranties. Solar Consultants expands those warranties to include labor for replacement of manufacturer warranted parts.

Solar Consultants warranty is void if the system has been allowed to run without fluid(s) or has been allowed to remain in a non-operating condition for more than thirty days.

Solar Consultants is not responsible for damage attributable to domestic water chemistry, including but not limited to hardness, acidity, or chloramines content.

Manufacturers’ Warranties (subject to change without notice)

Independent Energy “Goldline” controls carry a five-year pro-rated warranty.

Replacement the first three years is at no parts charge; three to five years at sixty percent of list price.

Taco pumps have a one-year replacement/repair warranty for the electrical portion and three years for the cartridge, which contains all the moving parts.

Armstrong/Wilo pumps are warranted for two years from date of shipment from factory.

Rheem/Richmond/Eagle Solar water heaters have six-year warranties.

Most brands of collectors carry a ten-year manufacturer’s warranty against defects or leakage, but not against damage from freezing or outside forces. (Homeowner’s insurance covers limb and storm damage.) Solar Consultants’ used collectors are warranted for five years against defects or leakage.

Send Us a Message

Contact Info

Fred Stewart

Licensed plumber and solar thermal system designer

Tom Willis

Licensed plumber and NABCEP-certified system designer

Richard Copsey

Installer/technician