Drainback Solar Water Heater using Rheem/Richmond/Eagle Solar SolarAide Integral Heat Exchanger Water Heater

View PDFContact UsUser’s Manual

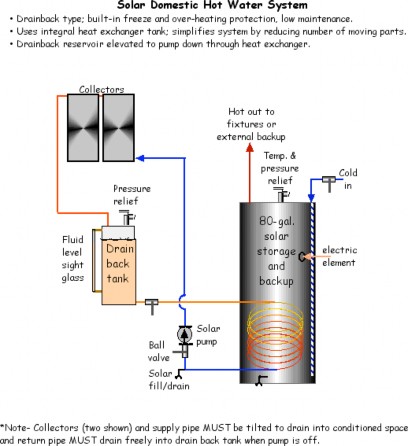

This manual describes our drainback type solar water heater with the following characteristics:

- Sealed solar fluid loop (no need to top up fluid seasonally as with systems that are open to the air.)

- Self-protected from freezing or overheating with or without electric power being on.

- Allows extra collectors for space heating.

- Backup can be the element built into the upper portion of the solar water heater, or can be separate water heater, gas or electric.

- Uses industry-standard circulators (pumps). Other brands can be substituted for replacement without system redesign.

Components

The solar loop of the system consists of a small (10-20 gallon) drainback reservoir to store solar fluid, a pressure relief valve, a pump to lift the fluid and move it through the collectors, one or more thermal collectors, and the heat exchanger built into the SolarAide water heater. The solar fluid is either plain water, water with a pink-tinted anti-corrosive buffer added (if the drainback reservoir is not stainless steel), or a propylene or ethylene glycol antifreeze mixture (if the reservoir is in an unconditioned space.) A boiler drain and fill plug are provided for maintenance.

The potable, or domestic hot water is stored in the 80-gallon electric water heater and does not mix with the solar fluid. The system may include a tempering valve to manage the outgoing water temperature.

The solar pump is controlled by a differential temperature control, typically a Steca TR0301, mounted on the side of a tank or wall near the solar pump. The control continually compares a temperature sensor at the top of the

collector array and one in the lower portion of the potable water storage tank to determine when to turn on the pump.

Description of Operation

When sunlight hits the collectors and their temperature rises to fifteen degrees higher than that of the coolest potable water at the bottom of the storage tank, the differential temperature control switches 120VAC power to the pump. The solar fluid is driven through the heat exchanger, up to fill the collectors and, after about two minutes, can be heard gurgling down the return pipe.

Pumping continues until the collectors and the stored water come within four degrees of each other, the pump turns off and all the solar fluid drains back to its holding tank. On a day with intense mottling of clouds and sun it is possible for the pump to stop and start several times. This happens especially when the storage water has already been heated to near collector temperatures.

Since the collectors and exposed pipes have no fluid in them when they are cold, no antifreeze is necessary, but if there is danger of the solar fluid storage tank freezing, antifreeze may be added.

The control includes an adjustable high temperature limit. When the lower storage tank temperature reaches the limit — usually set inside the control at around 110 to 130° — the control shuts off the pump even if the collectors are still hot. This would typically occur near the end of a sunny day when little domestic hot water or space heat had been used.

The operation of the backup water heater is covered in its own manual provided by the manufacturer.

Installation

This section is intended to inform the system owner of some of the considerations and logic that went into the installation of solar equipment. It may be helpful if a re-roofing, renovation, or other change demands part of the system be moved.

Collectors and Pipes

Your collectors may have been mounted using any of several methods, depending on whether the feet are attached directly to the collector frames or a separate aluminum frame was fabricated to hold the collectors; whether they are parallel with the roof surface or held up with legs, etc. On most roofs (other than standing seam metal) each foot has a stainless steel lag bolt that penetrates the roof into solid wood.

The collector array faces close to south at approximately a 45° angle from horizontal and is also very slightly tilted from vertical in an easterly or westerly direction (i.e., “crooked” on the roof) so that the bottom pipe of the collectors will drain. The minimum drain slope is 1 inch in 20 feet.

There must also be a similar continuous slope in the solar pipe runs from the lower end of the collector panels on the roof to the heat exchanger and solar fluid tank.

If the attic or other area where these pipes run is ever renovated, be certain the slope is not compromised. If the attic is used for storage make certain no heavy object is placed upon or hung from a pipe so as to bend it or cause a low spot.

If the collectors must be moved for roof repairs consult a solar installation professional beforehand.

Drainback Reservoir

The reservoir containing the solar fluid should be protected from rain and prolonged freezing temperatures in case of extended power failures. The preferred location is within the insulated area of a building. If it is installed in an attic, pipes to and from the backup water heater may be situated to provide some residual heat migration to prevent freezing, or antifreeze mixture may be used as the solar fluid.

Some models of drainback reservoirs are stainless steel and, when installed with a bronze pump, do not require any anti-corrosive buffer (“boiler treatment”). The solar fluid in those is plain water, unless the tank has to be located in an unconditioned space, as mentioned above.

The drainback and the domestic water tanks must be installed on a floor or surface substantial enough to carry the full weight of the tank plus water. The table below shows approximate filled weights of three common tanks. Drain pans should be used where leaks could damage flooring or floors below. As long as the anticorrosive additives in the drainback fluid are maintained, there is little chance of the tank rusting out as will a tank containing domestic water.

However, the tank should be accessible for maintenance, particularly the boiler drain at the bottom and fill plug in the piping above the tank.

Approximate Weight of Full Tanks

|

Tank Size |

Approx. Full Wt. |

Water Treatment (1:250) |

|

10 gal. |

125 lbs. |

8 oz. |

|

20 gal. |

210 lbs. |

16 oz. |

|

80 gal. |

870 lbs. |

Potable water |

|

120 gal. |

1300 lbs. |

Potable water |

Maintenance

The top level of the fluid (with pumps off and fluid drained back) should be within 5” of the top of tank level. See “Checking Level and Topping Up the Solar Fluid”, below. If the fluid in the tank is not plain water, the anti-corrosive buffer compound or antifreeze in the solar fluid should be tested at least every three years.

Since the pump is lubricated by the fluid it pumps, it requires no maintenance, but if it sits too long without running the fluid can leave deposits that will prevent the pump from being able to start without being either taken apart and freed up or replaced.

Indoor pipe insulation should be checked every few years. Patch any areas where shrinkage or damage has caused gaps to form, using insulation rated for high temperatures (rubber foam, isocyanurate foam, or fiberglass; not plastic foam.)

Animals — cats in particular — are attracted to the warmth of the system. The top of a tank makes a great place to sleep. You may have to wrap screen wire around insulation to keep them from tearing it.

Your water heater includes an anode rod that protects it from corrosion from the potable water. It should be checked every three to five years. If the electric element is wired up, turn off the electric element’s 240V (double) circuit breaker or pull the disconnect before draining any water or unscrewing the anode. To check the rod, turn off the cold water inlet and drain off the hot water pressure down to the top of the tank, then unscrew the sacrificial anode rod — it is the 1-1/16” hex-head in the top of the storage tank (water heater) — and pull it up to examine the rod. If it is deeply pitted or more than six inches of core wire is exposed at either end of the rod, replace it. After the anode is back in place and the cold water valve is back on, open several hot water taps long enough to blow air out of the tank and lines before restoring electric power to the element.

Checking Level and Topping Up the Solar Fluid

Unlike vented drainback systems (e.g., the Six Rivers or Astron SunMate brands), our solar fluid loop is sealed so there should be no evaporation under normal use. A sight glass on the reservoir side shows fluid level. Following are instructions for checking and topping up the fluid in case any is ever lost.

You’ll need: two wrenches or large pliers, one of which must have a

-

- /4″ jaw opening; funnel with ~1/2″ spout; Teflon™ pipe thread tape; a rag; a small bucket; and (if used in your system) propylene glycol antifreeze. If possible this procedure should be done when the drainback tank and collectors are not hot.

- Turn off or unplug the system’s differential temperature control. Wait five minutes for all the fluid to drain back into the holding tank.

- Observe the solar fluid drainback tank. Caution: this tank, its fittings, and the fluid may be very hot! Are there any signs of fluid leakage at the base or in the drain pan (if installed) under the tank? Any sign of drip or corrosion from leakage at the pressure relief valve, fill plug, on boiler drain? If so, note that and clean it off so you’ll be able to tell next time if there has been more leakage at these points.

- Use the rag and lift the lever on the pressure relief valve (PRV) to let off pressure. Try to leave this lever in the open position. (Some valves do not have a lever on top and should be removed during the draining or filling operation.)

- Some tanks use the PRV hole as the fill port, some have a separate plug, while some are filled via the drain valve. If yours is either of the first two types, place a wrench or pliers on the drain plug (in the pipe atop the drainback tank) or the PRV and the other on the outside of the fitting holding the plug and loosen the plug. Before it gets completely open, lift the PRV lever one more time or check to make sure it is open to make certain pressure is neutral. As a further precaution, place the rag over the plug and never look at or stand over the fill plug as you complete its removal.

- If your tank does not have a sight glass, use a dipstick to test the fluid level. If it is more than 5”below the fill hole level, fluid should be added. Either attach a hose to the boiler drain and force water into the tank or put a funnel in the fill hole and slowly add water or antifreeze/water mixture until the level is about 1” below the tank top.

- Wrap the plug or PRV threads with Teflon™ tape and replace.

- Release the PRV lever so it returns to a closed position.

- Make a note of how much water or antifreeze you added and the date. Plug in and/or turn on the differential temperature control. Listen for the pump to start and, in a minute or two, the solar fluid to begin returning to the drainback tank. Make sure to leave the control in its “Auto” setting of the function switch.

Warnings

It is acceptable, but not necessary, to turn off the system over vacation or time when no hot water is being used. If the pump is not run for months at a time, however, it may become stuck, requiring a service call to dismantle the pump body.

If the solar fluid pump is ever replaced, specify a new pump that has sufficient static head to push the fluid to the top of the collectors, plus a few feet extra to allow for pump aging.

Troubleshooting

If you are ever uncertain of whether the sun is heating your water or not, try turning off the backup, by switching off either the water heater element 240V breaker, the instantaneous backup, or the pump to the gas backup. Be sure that power is still on to the solar control. Leave it this way for at least a day. You should continue to have hot water as long as there is a reasonable amount of sunshine and you are not using more hot water than the system was designed to supply. (This test will work only if any space-heating load is minimal or nonexistent so as not to deplete the solar-heated water.)

The best basis for troubleshooting is to become familiar with the sounds the system makes in normal operation. Also, by feeling the pipes on a sunny midday you should be able to tell a difference in the temperature of the fluid

going up to the collectors and that returning. The return fluid should be warmer. But feel the pipe carefully; the returning fluid could be scalding hot!

The voltage to the temperature sensors is low, so it is perfectly safe to work with them while power to the differential temperature control is on. Steca sensors have a positive coefficient of temperature to resistance, so their resistance increases as does temperature where Goldline, Delta-T and some other controls’ sensors are thermistors with a negative coefficient of temperature to resistance, so a low resistance is analogous to a high temperature. If the Steca control display shows temperature readings that are out of touch with reality, either the sensor(s) or control should be replaced.

The pump bodies normally run hot to the touch. They should never become so hot as to discolor or blister their paint, however. Always unplug the control before servicing the pump.

The solar heating system is functionally independent of the backup water heating or space heating systems. If your water is not as hot as usual on cloudy days, the backup heater is likely the culprit. If it is continually lukewarm even though the water heater tanks are hot, the tempering valve is suspect.

| Symptom: | Likely Causes: |

| 1) Pump never runs. | 1a) If diff. temp. control LCD screen is not lit check the outlet or circuit breaker. The Steca has internal fuses with spares inside the case. |

| 1b) Check Steca display for error messages and check manual for interpretation. If none are displayed, use switch on side of Steca; move switch upward from AUTO to ON. This should force the pump on. If the pump comes on and runs normally the problem is in a sensor, sensor wiring, or internal to the control. Temperature sensor/wire at collector is open or sensor/wire at tank is shorted, or a sensor is defective. Disconnect sensor wires from control and test with ohmmeter. Control literature includes temperature/ resistance charts, or call Solar Consultants to find out if reading is normal. | |

| 2) Pump hums and gets hot but does not circulate fluid. | 2) Pump’s running capacitor or one winding is bad; rotor may be stuck or impeller or shaft broken. |

| 3) Pump runs all the time, 24 hours a day. | 3a) Test as 1b) above, but turn switch from AUTO to OFF. If pump(s) do not stop then relay in control is stuck on. |

| 3b) Temperature sensor/wire at collector is shorted or sensor/wire at tank is open, or sensor is defective. Test with ohmmeter. Control literature includes temperature/ resistance charts, or call Solar Consultants to find out if reading is normal. | |

| 4) Pump runs long after sun is down, but not all night. (In very hot weather pump could run all night.) | 4) System is not effectively getting heat from the collectors into the water. If the solar fluid tank is not hot, the solar fluid volume may be too low to fill collectors. |

| 5) System turns pump off even though the sun is still on the collectors. | 5) High temperature limit of storage water (usually 110 to 130° at bottom of tank) may have been reached. |

| 6) Steam hisses from the pressure relief valve on the solar fluid (drainback) tank. | 6) The solar loop is getting overly hot. There may not be enough fluid to complete the loop (listen for sound described in 7b). |

| 7) Noises | 7a) The pumps are lubricated by the water they pump. The noise should be a steady hum. “Bacon frying” or a soft “popcorn popping” indicates air in the lines. Solar fluid contacting hot collectors can flash into steam with a loud thump if the pump comes on after the collectors have been in full sun for awhile. |

| 7b) After the pumps have been running for two minutes or so, solar fluid may be heard coming down the return pipe. The sound is like a gurgling fountain and is normal. | |

| 7c) Screeching or clattering indicates pump bearings are shot; unplug the control immediately. | |

| 8) Water not hot enough | Determine the events that cause this. Is it true all the time (in which case the tempering (mixing) valve, if installed, is suspect), only when there has not been much sunshine (in which case the backup heating is not sufficient), or only when you turn off the backup (in which case the solar may not be fully functioning)? It is also possible you have begun using more hot water than your system was designed to provide. |

Notes Regarding Parts

- collector(s) are typically either SolarHot Silver or Platinum, Alternate Energy Technologies AE, or Solargenix Energy Winston Series.

- solar fluid (drainback) reservoir: stainless or steel tanks with a sight glass are specialized solar items, but any electric water heater of 10-30 gal. capacity may be substituted. Water heaters come with a temperature/pressure release safety valve. Since we are concerned only with excessive pressure, the temperature probe of the valve must be cut off.

- water heater: Rheem SolarAide (also sold under the Richmond and Eagle Solar brands). If replacement is necessary, other internal or integral heat exchanger water heaters may be substituted, or an external heat exchanger and potable pump may be added to a standard water heater.

- solar fluid pump: (depending on height to top of collectors) Taco 008 or 009 or Armstrong Astro 50 or 70 (or Wilo equivalents) cast iron or bronze, flange fitting. Taco, Inc., 1160 Cranston St., Cranston, RI 02920 or Armstrong Pumps, Inc., 93 East Ave, North Tonawanda, NY 14120. If a cast iron pump is used, solar fluid must contain anti-corrosive treatment.

- differential temperature control: Steca TR0301 (Memmingen, Germany, distributed in USA by SunEarth, 8425 Almeria Avenue, Fontana, CA 92335)

- All other parts are standard items obtainable from local plumbing or heating supplier.

Specifications

Electrical requirements (Watts @ 120vAC) typical: 90 maximum: 180 Options:

-

- Thermostatic mixing valve (tempering valve) for water heater outlet.

- Dial thermometers to indicate fluid temperatures.

- Remote temperature readout. Can be installed up to fifty feet away.

Design changes and part substitutions may be incorporated in custom or future systems.

Warranty

Parts and workmanship for a complete system installed and maintained by Solar Consultants are warranted by Solar Consultants for one year from the installation date. Individual parts, especially tanks, pumps, collectors, and controls, may be covered by additional manufacturers’ warranties. Solar Consultants expands those warranties to include labor for replacement of manufacturer warranted parts.

Solar Consultants’ warranty is void if the system has been allowed to run without fluid(s) or remain in a non-operating condition for more than thirty days.

Solar Consultants is not responsible for damage or loss of service attributable to domestic water chemistry, including but not limited to hardness, acidity, or chloramines content.

Manufacturers’ Warranties (subject to change without notice)

Steca controls carry a two year warranty.

Taco pumps have a one-year replacement/repair warranty for the electrical portion and three years for the cartridge, which contains all the moving parts. Armstrong/Wilo’s warranty is two years.

Rheem/Richmond/Eagle Solar water heaters have six-year warranties.

Most brands of collectors carry a ten-year manufacturer’s warranty against defects or leakage, but not against damage from freezing or outside forces. (Homeowner’s insurance covers limb and storm damage.) Solar Consultants’ used collectors are warranted for five years against defects or leakage.

Appendix: Steca Control manual, abridged

The most relevant parts of the Steca TR 0301 differential temperature control manual are reproduced here, with some notes as to how they are programmed in our installations. For more details and error codes, see your Steca manual or https://www.stecasolar.com/index.php?Steca_TR_0301_U_en

The control is normally in the Automatic mode, but can be switched to manual on or off for testing. The switch is recessed on the left side of the control, as pictured below.

Location of Manual On/Auto/Off Switch

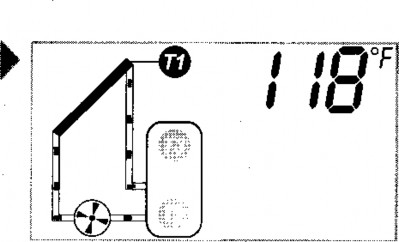

Typical operating screen, with temperature at collectors (T1) displayed.

Use arrow to switch to reading storage tank temperature.

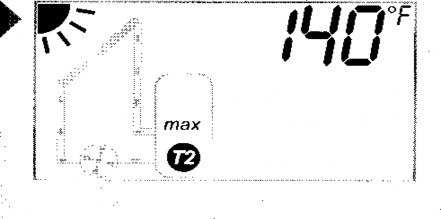

The storage tank has reached the programmed high limit, here set to 140°. “Max” flashes.

To change high limit, press “Set” for 2 seconds. The current tank temperature will be displayed and “T2” and “Max” flash on the tank. Press “Set” for 2 seconds again until the temperature flashes. Use up or down arrow to change; press “Set” to store.

Send Us a Message

Contact Info

Fred Stewart

Licensed plumber and solar thermal system designer

Tom Willis

Licensed plumber and NABCEP-certified system designer

Richard Copsey

Installer/technician